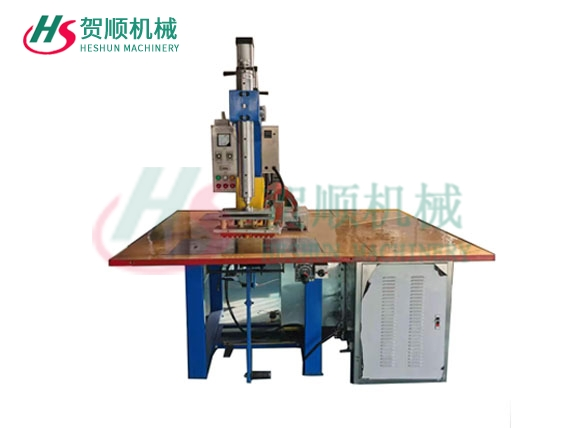

How to maintain the high frequency welding machine routinely?

When the high-frequency welding machine is heated, it is necessary to keep the mold and the rubber material clean, otherwise there will be a flashover phenomenon. If so, check whether the mold is burnt out. If there is a gap, it is necessary to repair it. If the mold is not clean, use mold washing water (day That water) clean up. The copper sheet of the grounding wire is often easily damaged by pressure, so replace it if necessary. The water in the compressed air will accumulate in the water bottle. Please clean the water in the water bottle before using the machine. If the lubricating oil in the lubricator is on the indicator line, special oil must be added (the lubricating oil should be corrosive oil, such as Jaguar (PS-5). The dust in the machine should be cleaned up once a month (except the oscillator in the Dust).

The mechanical activity part needs to be refueled every two to three months. 1. The fan does not work: check; 1 the input power is linearly cut off 2 the fan is damaged

Inspection method: Measure the input voltage 220V to check whether the fan coil is burned out and whether the fan blades rotate flexibly. 2. 3. 2. The turntable is not flexible: check steps: 1 input air pressure is insufficient or leaking 2. Rotary shaft burned out 3. Air cylinder pushing the shaft is damaged 4. Solenoid valve damage inspection method: 1 Check the air pressure reading 4KG-6K air Check if the throat is leaking 2 Take out and check if the gas cylinder is normal 3 Directly connected to 220V electricity and check 3. The gas cylinder cannot push the mold down: Check steps: 1 The turntable triggers the microphone failure 2 The fall time system is damaged 3 The gas cylinder is damaged 4 The solenoid valve is damaged 5 Relay damage inspection method: 1 Check the contact position and test the microphone system 2 Replacement certificate is damaged 3 Connect to the air source test 4 Directly connected to 220V electricity inspection 5 Replacement inspection 4. Work mode flashover: monitoring steps: 1 Excessive output force 2 Insufficient mold heat 3 Mold and welded material are not parallel 4 Insufficient air pressure Check method: 1 Reduce the output and check whether the heater indicator light is on, if it lights up, it indicates that the temperature is insufficient (indicating about 140 ℃) 2 See if the upper and lower molds are parallel and normal is 4KG -6KG5. No high-frequency output: 1 Filament transformer is damaged 2 High-cycle transformer is damaged 3 Grid resistance is burned 4 Electronic tube damage inspection method: 1 Transformer input 220V output 6.3V 2 Input 220V, output 7500V resistance is normal 3 Change tube 6. Heater No heat output: inspection steps: 1 heating wire burned 2 thermostat damage inspection method: 1 measuring the resistance of the heating wire 2 replacing the thermostat .

He Shun (Shenzhen) Machinery Equipment Co., Ltd.

Contact: Mr. Yang

Mobile phone: 13600429568

Mailbox: hs@hsszjx.com

Website: www.hsszjx.com

Address: 3D, Building 4, No. 12, Jiangshi First Industrial Zone, Jiangwei Community, Matian Street, Guangming District, Shenzhen

微信二维码 手机官网