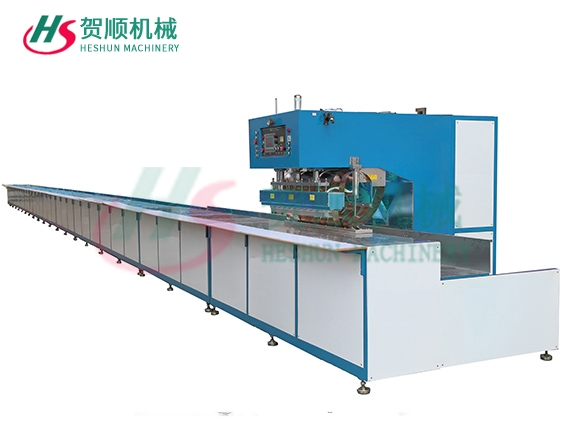

Product name: 25KW high frequency membrane structure welding machine

1. Product features:

1. The high-sensitivity spark protector reduces the damage of the mold to a lower level during ignition, which greatly reduces the product loss rate.

2. Over-current protection circuit to avoid overloading of the tube and prolong the service life of the tube.

3. Adopting European standard square high-frequency oscillation box design, excellent and reasonable oscillation loop system, so that high-frequency output is stable and output is greater.

4. The introduction of Taiwanese technology has beautiful appearance, reasonable design, novel structure, reliable performance and strong practicability.

5. Use advanced high-cycle shielding technology to ensure no high-cycle leakage.

6. The machine can be designed according to the needs of the product to quickly complete the welding of the product.

7. The welding is firm and stable, and the thickness of the material can be satisfied.

8. The machine has a large space for the material tank, which is convenient for continuous connection in a large area.

9. The use of rear grounding clamps facilitates operation and prevents operators from being injured.

10. According to user needs, choose models with different high-frequency power, and the length and width of the welding material can be changed by changing the size of the high-frequency mold to achieve the welding needs of the membrane structure or canvas.

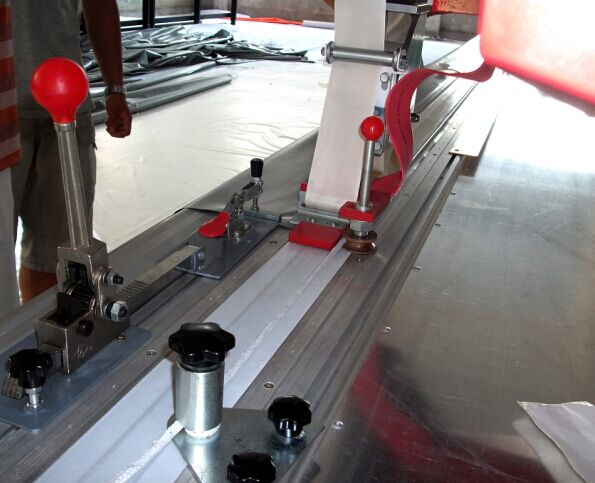

11. The inside of the machine is equipped with a discharge trough with a corresponding span. The span and depth of the discharge trough can be selected according to the size of the product welded by the customer. Can meet different sizes of canvas welding and connection.

12. The laser scanning positioning system of the high-frequency membrane structure canvas welding machine is an optional configuration, which is convenient for precise positioning during each welding operation

13. The automatic frequency tracking system of the high-frequency membrane structure canvas welding machine is an optional configuration to ensure that the high-frequency current during each welding is at a constant set value.

14. Using intelligent PLC man-machine interface operating system, stepping or servo motor drive. Automatic walking, precise position, realizing automatic welding of membrane structure or canvas without moving materials and machines. One seam is completed at one time, the seams are neat, without wrinkles and knife marks. The welding speed can reach 5-10m per minute.

2. Product application:

High-frequency inflatable membrane structure welding machine is dedicated to the welding of membrane structure, inflatable membrane structure, tensile membrane structure, canvas, tent tensile membrane, outdoor membrane structure, outdoor shade cloth, advertising printing cloth, PVC coated cloth, and fast rolling door materials , It can also be used for seamless splicing of materials such as soft biogas digesters, biogas storage bags, and soft oil storage tanks.

Third, the principle of high frequency film structure welding heat sealing:

The working principle of the high-frequency inflatable membrane structure welding machine: the dielectric material (PVC membrane material) activates the positively charged molecules under the action of high-frequency electromagnetic, so that the positively charged molecules of the dielectric material move at a high speed, and the friction generates heat. The purpose of welding.

High-frequency membrane structure welding machine\membrane structure heat sealing machine adopts the principle of high-frequency, used for high-frequency tarpaulin canvas connection, high-frequency film curtain welding, high-frequency outdoor shading cloth welding, high-frequency advertising printing cloth welding, high-frequency tent cloth welding , High-frequency film structure splicing, outdoor film structure welding, film structure welding, high-frequency PVC cloth welding or high-frequency welding or splicing of any soft plastic plastic material containing PVC components. After the action of high frequency waves, the surface of the materials welded by high frequency is smooth and flat, beautiful and firm.

Fourth, machine parameters: high-frequency membrane structure welding machine specifications:

Model: | HS-8KWFZ | HS-10KWFZ | HS-12KWFZ | HS-15KWFZ | HS-25KWFZ1 |

High frequency power: | 8KW | 10KW | 12KW | 15KW | 25KW |

input power: | 15KVA | 18KVA | 20KVA | 25KVA | 35KVA |

Vibration tube: | 7T69RB | E3069 | E3130 | 8T85RB | 8T25RA |

Under pressure: | 500KG | 600KG | 800KG | 1000KG | 1500KG |

Upper die clamp size: | 50*50*800MM | 50*50*800MM | 50*50*900MM | 60*60*900MM | 50*50*1000MM |

Electric rectifier: | Silicon Diode | Silicon Diode | Silicon Diode | Silicon Diode | Silicon Diode |

Electrode interval: | 150MM | 150MM | 150MM | 150MM | 150MM |

Die stroke: | 150MM | 150MM | 150MM | 150MM | 150MM |

voltage: | AC380V 3P 50/60HZ | AC380V 3P 50/60HZ | AC380V 3P 50/60HZ | AC380V 3P 50/60HZ | AC380V 3P 50/60HZ |

Frequency: | 27.12MHZ | 27.12MHZ | 27.12MHZ | 27.12MHZ | 27.12MHZ |

Pressure method: | Air hydraulic drive | Air hydraulic drive | Air hydraulic drive | Air hydraulic drive | Air hydraulic drive |

Splicing time: | 0-10 seconds | 0-10 seconds | 0-10 seconds | 0-10 seconds | 0-10 seconds |

<All specifications related to the machine can be customized according to user requirements. Due to the need for improvement, there will be no notice for specification changes>

Product application case:

He Shun (Shenzhen) Machinery Equipment Co., Ltd.

Contact: Mr. Yang

Mobile phone: 13600429568

Mailbox: hs@hsszjx.com

Website: www.hsszjx.com

Address: 3D, Building 4, No. 12, Jiangshi First Industrial Zone, Jiangwei Community, Matian Street, Guangming District, Shenzhen

微信二维码 手机官网